Image: Daniel Klockars works with weaner, sow, and finisher feed at A-Rehu, a subsidy to the finish meat producer Atria. The company is working to eliminate soy in pig feed to reduce the climate impact of pork.

FINNISH PORK PRODUCER AHEAD OF THE CLIMATE CHALLENGE

The pork producer Atria has succeeded in making soy-free feeding concepts for pigs. Their toolbox consists of local protein sources and fermented proteins.

Focusing on lowering CO2-impact of pork

The most significant contributor of CO2 in meat production is feed. As a result, Atria and its feed producer, A-Rehu, are focusing on reducing the CO2 emission of feed in their quest to become the most sustainable meat producer. The means to get there include more locally produced crops, using by-products and excluding soy in pig diets.

We have interviewed Daniel Klockars, Account Manager for piglet, sow, and finisher feed in A-Rehu, to understand more about the Finnish way of feeding for improved health and reduced CO2e- emissions of pork.

Soy-free Pork with lower CO2 emissions

Atria has conducted trials with a new soy-free feeding strategy to test how climate-friendly pork becomes without soy. Results show that soy-free pork has a considerably lower CO2 emission than soy-fed pigs. Exactly how much A-Rehu has managed to reduce emissions has not yet been made public.

– Soy-free pork has an even lower CO2 emission than pigs fed certified soy. We conducted the trial for two years, and in the coming years, we will introduce it to the rest of our owners, says Daniel Klockars.

CO2-emissions on display

On Atria’s meat packaging, CO2 emission is displayed, allowing consumers to compare emissions of different types of meat. But CO2 labelling comes with a need for education – a communication task that Atria is taking on:

-Consumers have no reference to climate emissions on the packaging – they have nothing to compare to. For example, an old term like GMO-free, which the industry has communicated for years, is still unknown to many consumers. The entire industry has a task ahead of us, Daniel underlines.

Image: Current meat packaging from Atria with CO2e emissions of 2,1 kg/600 grams of pork

Soy-free finishers

In Finland, 83% of slaughtered pigs are fed liquid feeding. The trend of liquid feeding started about 30 years ago when by-products from dairy and liquid barley protein were used in pig feed to improve cost-efficiency – very much like in Denmark.

Liquid feeding has been one of the key reasons why Finnish producers can replace soy with a cheap alternative in finishers:

– For the last 5-6 years, we have fed soy-free feed for finishers from 30 to 100 kilos. We use liquid barley protein instead of soybean meal, with 41 per cent protein and 23 per cent dry matter. Liquid barley is a by-product of starch and ethanol production. The barley protein is used for 90-95 per cent of our farmers’ finishers. For the production of finishers, the use of liquid barley protein is about 178 litres, which reduces the need for grain by 23 kilos and 22 kilos of supplementary feed.

Both the supplementary feed and liquid barley proteins used for finishers are mixed and produced by A-Rehu.

Around 2 per cent soy in Finnish pig feed

Replacing soybean meal for finishers is one thing, but replacing soy protein for weaners and sows proves another challenge.

Young pigs have immature guts, which reduce their digestive capacities, and sows need nutritious feed to support milk production during lactation. Even though some barley protein is fed to weaners and sows, soy remains an excellent source of protein and essential amino acids for young pigs despite its negative climate impact:

– Today, the average pig feed consists of around 2 per cent soy – primarily fed during weaning. Soy is still a good protein for weaners. But for the last couple of years, we have been trying to reduce the use and replace it with local sources. We use the fermented soy protein EP200 in our supplementary feed, and a big part of the 2 per cent soy in pig feed comes from EP200.

In comparison with Atria, soy makes up 10-15 per cent [1] of Danish pig diets.

Secondly, the Finnish feed producer uses the fermented rapeseed meal for weaners, EP100i, and the fermented rapeseed meal and seaweed for sows, EP199, to support health, diverse gut microflora and high milk production.

The fermented soybean meal, rapeseed meal and seaweed proteins come from the Danish producer, European Protein, who is feeding sows and weaners with fermented feed from its factories in Denmark, Ukraine, and the US as well.

[1] https://www.danishcrownprofessional.com/viden/ansvarlig-sojaproduktion-skal-beskytte-regnskoven/

One step ahead

In 2018, Atria chose to certify all its soy with the Round Table of Responsible Soy (RTFS) but took it a step further and set a target of eliminating soy from pig feed entirely.

A-Rehu has also tested alternatives like corn, potato gluten and peas, to find local feed solutions – but protein from grass will not be a solution for the feed producer:

– We use peas, but mainly for poultry, not for pigs. Unfortunately, the current production of peas in Finland doesn’t cover our needs. However, as fertilizer prices increased last year and grain prices fell, more farmers are producing peas and fava beans, so this year will be an excellent pea year. Potato protein is also interesting for pigs but, unfortunately, too expensive, as is grass protein, according to Daniel.

Fermented protein for soy-free production

In 2013, the first Finnish farmer started feeding fermented proteins from Denmark, and this year, the farm celebrates its 10th anniversary with the fermented rapeseed protein EP100i. The same farm was the first to use fermented rapeseed and seaweed protein, EP199, for its sows and is still using it with good results. A-Rehu is now planning to use the fermented feed directly in its supplements to lower the soy protein content:

– EP100i is good for soy-free weaners because we get a high protein content. A farmer had specific problems with bacteria, but after using the fermented feed, he called me and said, ‘Maybe they are speaking the truth back in Denmark’, so he was pleased. We use EP100i up to 30 kilos, says Daniel, explaining his plan for the sow protein EP199:

– EP199 is used for sows, and we aim to use it directly in the supplements for sows. We can see that EP products are very effective against Lawsonia. Medications go down, and we have fewer diarrhoea incidences. So it’s good feed, Daniel concludes.

According to European Protein, fermented proteins increase the bacterial diversity in the gut microflora, which makes less room for pathogenic bacteria to colonize and dominate the microflora.

Replacing soy with fermented rapeseed

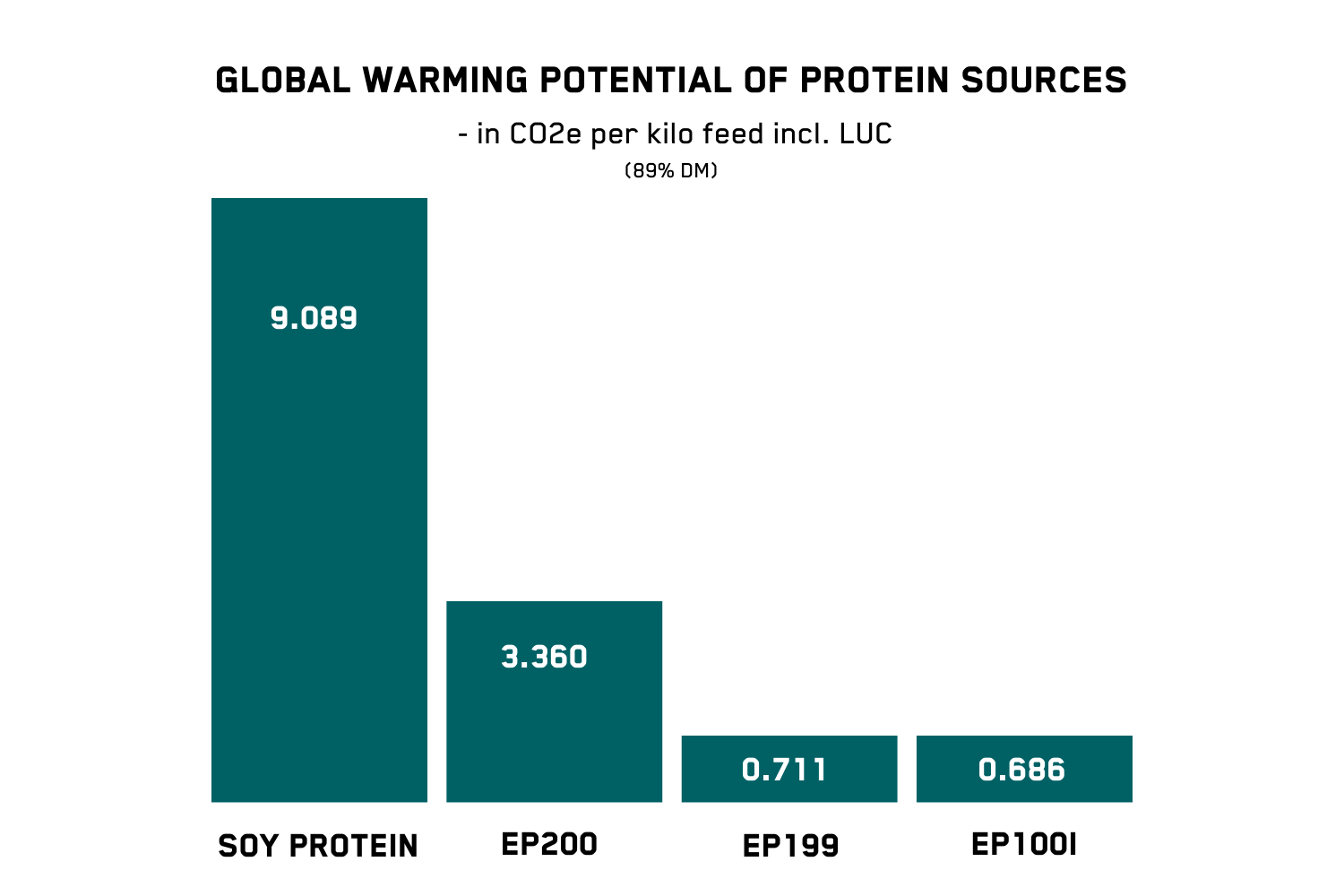

Fermented proteins consisting of rapeseed, rapeseed combined with seaweed or soy from European Protein have a lower climate impact than soybean meal and soy protein concentrate, respectively.

Replacing traditional soybean meal for sows with fermented rapeseed and seaweed protein reduces the climate impact by 89 per cent from 6.218 CO2e/kg feed (SEGES, GFLI-data) to 0.711 CO2e/kg feed (Bureau Veritas, 2023). If the soybean meal used is certified, the reduction amounts to 40 per cent.

Replacing soy protein concentrate for weaners with fermented rapeseed, EP100i reduces the environmental impact by 92 per cent from 9.089 CO2e/kg feed (SEGES) to 0.686 CO2e/kg feed (Bureau Veritas, 2023). If the soy protein concentrate is certified, the reduction amounts to 65 per cent.

Replacing traditional soy protein with fermented soy protein, EP200 reduces the impact by 63 per cent from 9.088 CO2e/kg feed (SEGES) to 3.360 CO2e/kg feed (Bureau Veritas, 2023). If the soy used is certified, the reduction amounts to 57 per cent.

To get a precise estimate, ask your supplier for the climate data on your current feed solutions.

Table: EP100i, EP200 and EP199: Product Environmental Footprint calculation of Global Warming Potential (GWP) of fermented complementary feed from cradle to gate produced at European Proteins factory site in Denmark in bulk. Calculated by Bureau Veritas HSE Denmark following the LCA and PEF core rules from ISO 14025:2006 and EU COM EF Annex 1 and 2, 2023, version 1.1. The calculated GWP-values are subject to continuous improvements and will be revised regularly as processes and inputs are optimized. Soy Protein Concentrate: Source, Danish Pig Research Centre, Feeding table, at gate in Denmark.

More fibres and long tails

Finland is known for its proactive policies on animal welfare, and long tails have for many years been standard on Finnish farms:

– We have had long tails for a long time, and reducing the use of zinc oxide has not been a challenge. We are used to tackling challenges and using toys, much space per pig, and other types of activation.

Different types of fibres are in focus at A-Rehu. Fiber levels are adjusted individually from farm to farm, but fibres are typically increased at farms experiencing challenges:

-We use many different fibre types. When we look at the recommended fibre levels, we are a bit higher, which we use as a preventive measure for tail biting. Fibers give well-being and a feeling of being full. If the pigs are not fed often, fibres help reduce hunger and tail biting, says Daniel.

Check your toxin levels

According to Daniel, many tail bites are caused by toxins in the feedstock, and pigs are more easily affected than other animals. He encourages farmers to analyze toxins in the raw materials:

– DON levels increased in barley and wheat last year, so we use toxin binders directly through the supplementary feed. But also in the complete feed afterwards. A lot of tail biting comes from toxins. It is frightening to look at the toxin levels. It’s not the same with chickens and cattle – they are more tolerant of toxins. So, you need to start if you are not already analyzing for toxins in the feedstock.

The Atria Group is one of Northern Europe’s leading meat and food industry companies.

This year, Atria is celebrating a food journey that began 120 years ago on Finnish family farms, whose recipe will last for generations to come: Good food – better mood. Atria produces meat from poultry, pork, and beef. The co-op consists of just below 300 pig farms with around 23,000 sows. The A-Rehu subsidy makes feed for poultry, cattle, and swine. A-Rehu is looking to reduce and replace the use of soy with local and more sustainable feed sources. Go to www.atria.com for more information.

BECOME PART OF THE SOLUTION

Feed accounts for up to 70 per cent of a pig’s carbon emissions. With fermented protein in pig feed, you can become part of the solution for tomorrow – starting today.

WANT TO KNOW MORE ABOUT FERMENTED PROTEINS?

If you would like to hear more about fermented proteins for pigs, please fill out the form below, and we will contact you via email or phone – completely obligation-free.

PROTEINS

For more information about our fermented proteins

ABOUT EUROPEAN PROTEIN

European Protein is a Danish family-owned protein producer. We work to promote health and productivity for animals through functional and sustainable plant proteins. The company was founded in 2011 and has protein factories in Denmark, Ukraine and the US.

HEAD QUARTER

European Protein A/S

Vorbassevej 12, 6622 Bække, Denmark

+45 75 38 80 40, [email protected]

VAT No. 33643675

FACTORIES

Denmark

Mangehøje 4, 7300 Jelling, Denmark

+45 75 38 80 40, [email protected]

Ukraine

222-a Vokzalna Street, Rokytne 09600, Kyiv Region, Ukraine

+38 044 390 40 54, [email protected]

USA

1201 N Ellis Rd #7055, Sioux Falls, SD 57107, USA

+1 605-338-9775, [email protected]