Image: European Protein has published its Product Environmental Footprint on fermented proteins to help pig producers lower their CO2e-emissions from feed (Left: Pia Sørensen, feed advisor, European Protein

Helping pig producers to reduce the environmental footprint of their protein feed.

The Danish producer, European Protein, has published its environmental footprint of their lacto-fermented protein solutions to help farmers reduce their greenhouse gas emissions from feed. With a saving potential of up to 92 per cent of CO2e from refined proteins in feed, farmers finally have an opportunity to choose a more sustainable refined feed source for their animals – without increasing costs or reducing productivity.

Saving CO2-e with fermented proteins

Animal feed accounts for up to 70% of the Environmental Footprint of meat production. Refined protein sources typically used in weaner feed have higher relative contributions to the CO2 e-calculation than unrefined feedstock, making it more critical for protein producers to help farmers find more sustainable solutions for their livestock.

European Protein produces both the conventional fermented soy protein, EP200, fermented soy protein with seaweed, EP229, but also offers fermented rapeseed meal, EP100i, and fermented rapeseed meal and seaweed, EP199.

Unlike soy, rapeseed meal and seaweeds are grown locally. All four products can be fed to weaners and wholly or partially replace traditional soy protein concentrates or fishmeal. So, opportunities to save on CO2e are plenty, says Pia Sørensen, feed advisor in European Protein.

“The fermented proteins make sense for both pig producers and feed producers environmentally and economically, and so our customers see it as a win-win situation. Now, they have a CO2-e value to use in their carbon footprint tools to document that they have made an active choice benefiting not only their animals but also the environment”.

Using local protein sources in weaner feed

Reductions depend on the type of protein replaced and what it is replaced by. But there’s no doubt what will reduce CO2e the most, namely shifting from soy protein concentrate to fermented rapeseed meal, EP100i or the seaweed-infused version, EP199.

Suppose soy protein concentrate is replaced one-to-one with fermented rapeseedmeal. In that case, farmers save up to 92% of their CO2e emissions related to the refined protein part of their feed, 91% from soy protein concentrate to fermented rapeseed meal with seaweed and 61% when replacing soy protein concentrate with European Proteins fermented soybean meal. The precise savings depend on the individual farmers’ feed formulations.

Sustainability is a bound task for all feed producers

In 2022, the European Proteins management team decided to invest in external documentation of the environmental footprint of lacto-fermented proteins. The CEO, Jens Legarth, recently received a 66-page long report from Bureau Veritas, who has been responsible for all calculations:

“The technology behind lacto-fermentation is accepted to be more sustainable in terms of energy and water usage than traditional protein refinement processes, but we would like to improve further. We, and the rest of the feed industry, need documentation based on the same methodology to calculate the footprint of the entire value chain to reduce CO2-e of food production. At European Protein, we have chosen to work with external experts like Bureau Veritas to help us conduct our Life Cycle Assessment to verify the environmental footprint of our fermented proteins.

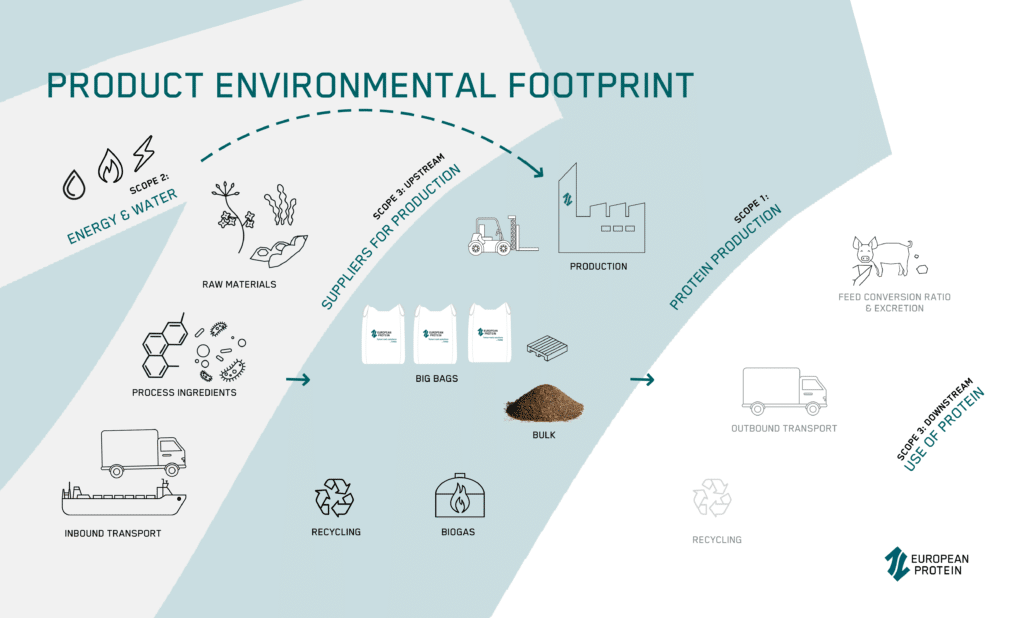

Bureau Veritas has used the PEF method for the report, short for Product Environmental Footprint, set out by the European Commission, which ensures comparable data between feed products. The calculations cover cradle-to-gate, meaning from the crop production to the finished product supplied by the factory in Denmark.

Conventional Soy Protein Concentrate: 8.75 CO2e/kg feed with LUC. Kilo CO2e/kilo feed delivered in Denmark: Data from Danish Pig Research Institutes’ Feeding Table

Image: Overview of the scopes included in European Proteins Product Environmental Footprint (PEF) on fermented proteins

PRODUCT ENVIRONMENTAL FOOTPRINTof lacto-fermented protein – bulk |

|||

PRODUCT NAME |

GWPkg CO2eq /kg product with LUC bulk (Land Use Change) |

GWPkg CO2eq/kg product without LUC in bulk |

PRODUCT DESCRIPTION |

| EP100i | 0.686 | 0.615 | Fermented rapeseed meal/canola |

| EP200 | 3.360 | 0.757 | Fermented soybean meal |

| EP119 | 0.740 | 0.670 | Fermented rapeseed meal/canola and seaweed |

| EP199 | 0.711 | 0.641 | Fermented rapeseed meal/canola and seaweed |

| EP229 | 3.320 | 0.807 | Fermented soybean meal and seaweed |

| Product Environmental Footprint calculation of Global Warming Potential (GWP) of fermented complementary feed from cradle to gate produced in bulk at European Proteins factory site in Denmark. Calculated by Bureau Veritas HSE Denmark following the LCA and PEF core rules from ISO 14025:2006 and EU COM EF Annex 1 and 2, 2023, version 1.1. The calculated GWP-values are subject to continuous improvements and will be revised regularly as processes and inputs are optimized. | |||

PRODUCT ENVIRONMENTAL FOOTPRINTof lacto-fermented protein – in big bags |

|||

PRODUCT NAME |

GWPkg CO2eq /kg product ct with LUC (Land Use Change) in big bags |

GWPkg CO2eq/kg product without LUC in big bags |

PRODUCT DESCRIPTION |

| EP100i | 0.733 | 0.661 | Fermented rapeseed meal/canola |

| EP200 | 3.403 | 0.804 | Fermented soybean meal |

| EP119 | 0.786 | 0.716 | Fermented rapeseed meal/canola and seaweed |

| EP199 | 0.762 | 0.691 | Fermented rapeseed meal/canola and seaweed |

| EP229 | 3.367 | 0.853 | Fermented soybean meal and seaweed |

| Product Environmental Footprint calculation of Global Warming Potential (GWP) of fermented complementary feed from cradle to gate produced at European Proteins factory site in Denmark in big bags on pallets. Calculated by Bureau Veritas HSE Denmark following the LCA and PEF core rules from ISO 14025:2006 and EU COM EF Annex 1 and 2, 2023, version 1.1. The calculated GWP-values are subject to continuous improvements and will be revised regularly as processes and inputs are optimized. | |||

PROTEINS

For more information about our fermented proteins

ABOUT EUROPEAN PROTEIN

European Protein is a Danish family-owned protein producer. We work to promote health and productivity for animals through functional and sustainable plant proteins. The company was founded in 2011 and has protein factories in Denmark, Ukraine and the US.

HEAD QUARTER

European Protein A/S

Vorbassevej 12, 6622 Bække, Denmark

+45 75 38 80 40, [email protected]

VAT No. 33643675

FACTORIES

Denmark

Mangehøje 4, 7300 Jelling, Denmark

+45 75 38 80 40, [email protected]

Ukraine

222-a Vokzalna Street, Rokytne 09600, Kyiv Region, Ukraine

+38 044 390 40 54, [email protected]

USA

1201 N Ellis Rd #7055, Sioux Falls, SD 57107, USA

+1 605-338-9775, [email protected]