What is fermented soybean meal?

Do you want to know more about soybean meal fermentation? Then you’ve come to the right place.

Let us take you through the most critical points of soybean meal fermentation.

You can read about reasons for fermenting.

Which techniques exist, and which are the most effective concerning cost, waste, energy and water consumption.

You can jump to the specific headlines here:

- Why is soybean meal fermented?

- What happens when soy is fermented?

- Fermentation cuts protein into peptides

- Fermentation breaks down ANFs in soy

- Fermentation produces new beneficial compounds

- What are the advantages of feeding fermented soy?

- What is the difference between wet and dry fermentation?

- Climate impact of soy

What is fermentation?

Fermentation is a biological process where carbohydrates metabolise to lactic acid or ethanol and CO2 during anaerobe conditions. The method has been used for over a thousand years to preserve food through uncontrolled fermentation.

Today we have learned how to master the technique and make a controlled fermentation to produce medicine and highly digestible feed.

You might already know the process of fermentation from your everyday life.

Lacto fermentation, you may know from sports, when you feel your muscles cramping up. It’s the body converting sugar to lactic acid. And alcohol fermentation, you know, from beer production.

In the feed industry, fermentation is used for making protein feed for young animals because fermented feed is easier to digest than the unfermented feedstock. Fermentation is also used to produce functional feed ingredients for animals.

The technology can be used on many types of plant protein but is mainly used for soy protein production.

Find out why below.

Why is soybean meal fermented?

Soybeans have a high content of protein and a favourable amino acid profile, which means that soybeans have all the essential amino acids the animals need and cannot produce themselves. In other words, soybeans are a complete protein contributing to young animals’ healthy growth.

When soy is fermented, the animals better utilise the protein, minerals, vitamins, and energy.

Soybeans contain several unwanted substances called ANFs, short for AntiNutritional Factors, which are counterproductive for especially young animals. Fermentation helps reduce these unwanted compounds.

Image 1: Fermented soybean meal supports healthy growth

What does fermented soy contain?

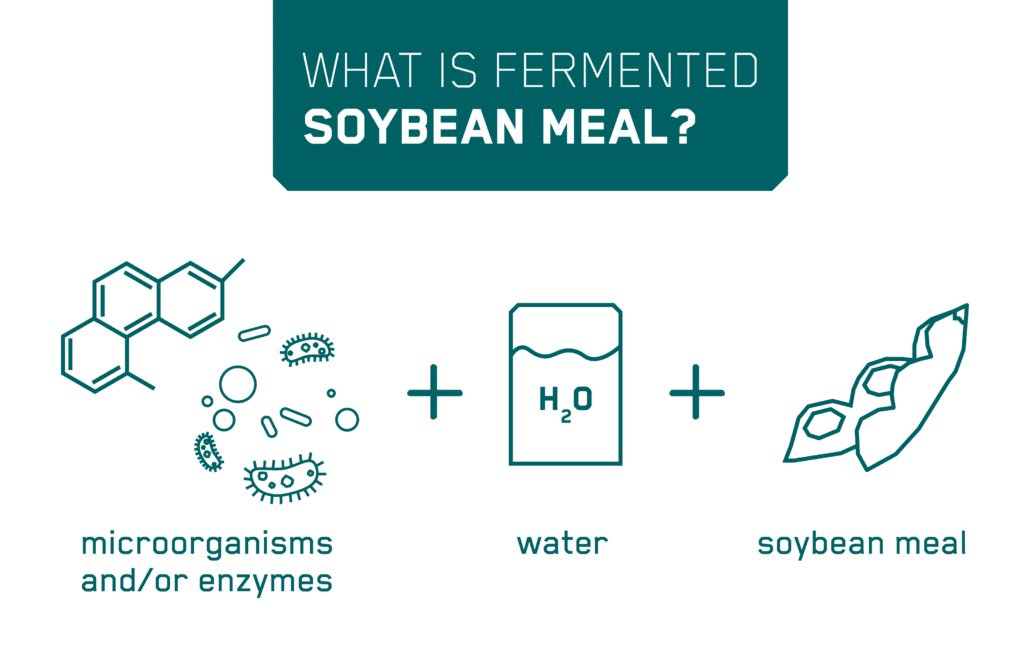

Fermented soy consists of a soybean meal, which has gone through a biological process called fermentation. The most common ingredients are soybean meal, water, lactic acid bacteria, fungus, yeast, enzymes, or a mix.

To put it more simply than it is: Soy is mixed with one or more of the mentioned microorganisms. Then the feedstock is fermented at a fixed temperature for hours or days during anaerobe conditions. And lastly, the product is dried and sold as a protein ingredient for animal feed.

Image 2: Elements in fermentation of soybean meal

What happens when soy is fermented?

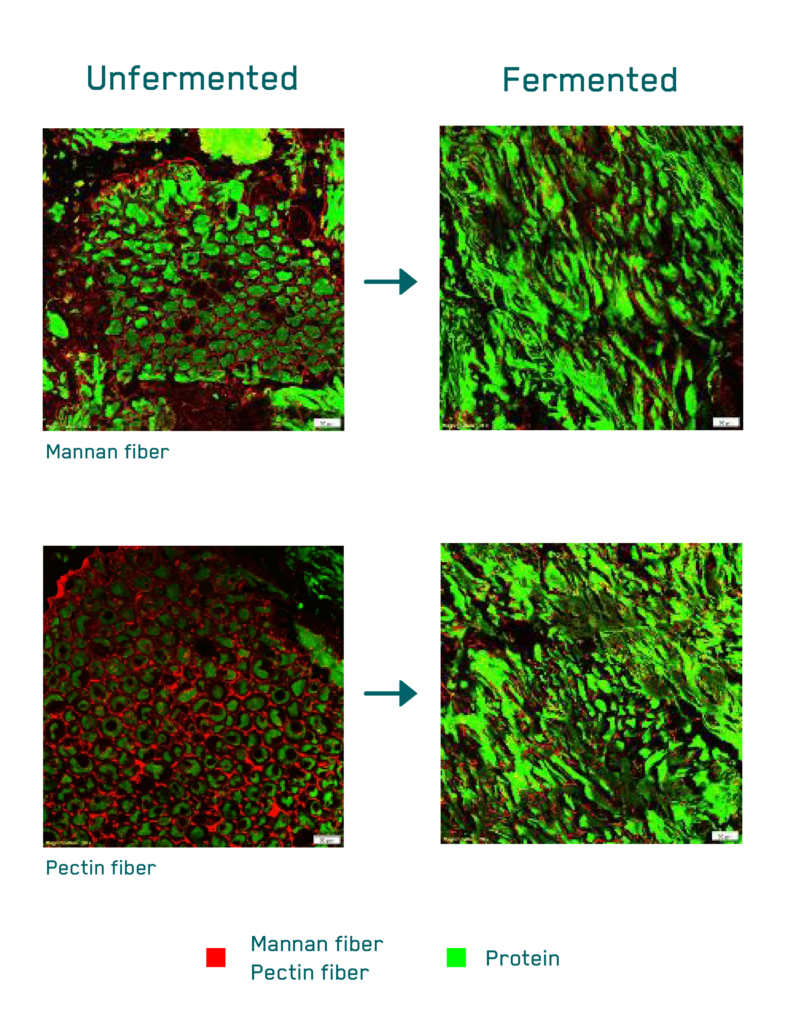

The cell walls surrounding the protein are broken down during the fermentation process. As a result, the animal gains access to the protein content in the middle.

Image 3: Cell of protein and fibre signals

In image 4, you can see soybean meal before and after lacto-fermentation. The red colour is a signal from the fibres inside the cell wall of soybean meal. The green colour is a signal for protein. Image 4 shows mannan and pectin fibres present in the cell walls.

When looking closer, you can see that the red rings surrounding the protein are fragmented after fermentation – giving easy access to the protein.

The undigestible fibres in the cell walls feed the gut bacteria. And when the fibres are broken into shorter chains, the gut can more easily feed on the fibres and produce short-chained fatty acids (SCFA), helping to maintain the integrity and health of the gut lining.

Image 4: Signals from fibre in the cell wall of soybean meal (red) and protein (green) before and after fermentation

Fermentation cuts protein into peptides

During fermentation, protein is cut into smaller peptides, which are easier to absorb through the gut.

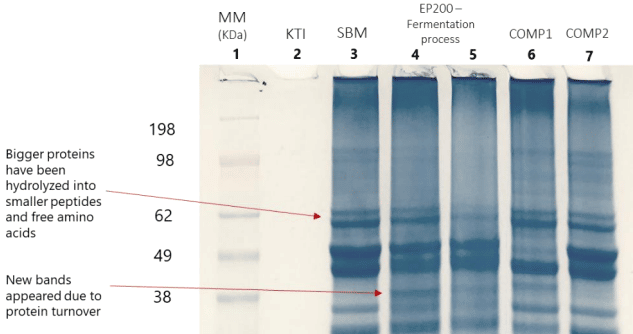

Using a measuring method called SDS page, we can check how effectively fermentation ‘cuts’ protein into smaller pieces.

A thick band show a high concentration of protein with similar molecular mass, as opposed to a faded colour, which shows protein broken into different sizes.

In image 5, the SDS page shows the difference between soybean meal (SBM) in column 3 and lacto-fermented soybean meal (EP200) in columns 4 and 5.

The protein placed at the top of the lanes around 75 (Kilo Dalton) are harder to digest, and the proteins placed further down are smaller and easier to digest through the gut.

The proteins are cut into smaller pieces during fermentation and “sink” to the bottom.

If you imagine a finely masked sieve, very little of the unfermented soybean meal (SBM 3) will pass through the sieve and reach the next level below. Unlike column number 5, where the protein has been cut and passes through the sieve.

Image 5: SDS page of different fermentation methods and its influence on protein size and the break down of antinutritional factors

Fermentation breaks down ANFs in soy

Soybean holds several compounds that have a negative influence on growth. We call them Anti-Nutritional-Factors or ANFs.

The presence of ANFs means that untreated soybean meal has a limited inclusion rate for young animals. For fully grown animals, the ANFs mean less.

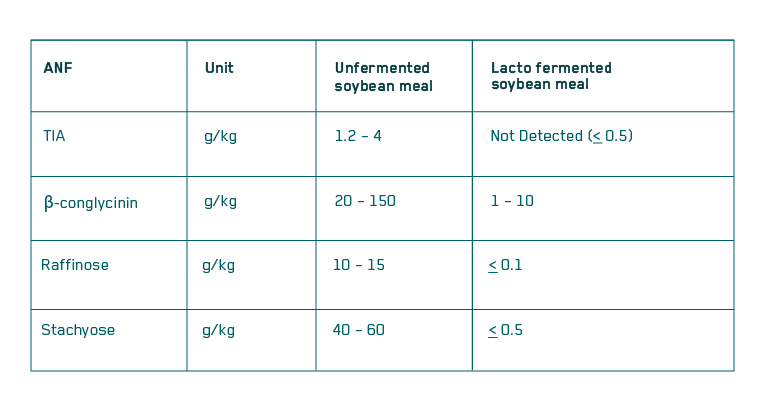

Fermentation can remove a fair amount of the ANFs, making soy protein suitable for feed for even the youngest and most vulnerable animals. In the table, you can read the amount of ANFs before and after fermentation.

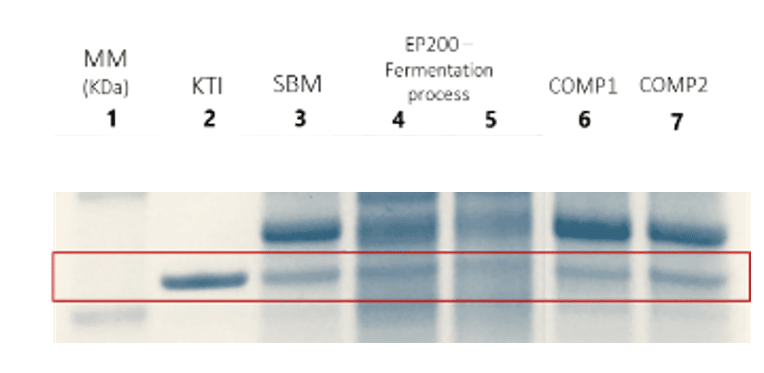

Let’s jump back to the SDS page gel highlighted in image 6 below.

On the gel, you see a line of thick bands. The band shows proteins of the same molecular weight. Some of the band placement on the gel reveals that ANFs are present in the feedstock. When the bands fade after fermentation, it means that the number of ANFs is reduced.

The coloumns shows a comparison of Kunitz Trypsin inhibitors (KTI or TI) in soybean meal (SBM 3) and EP200 (4+5) and two of our colleague’s soy proteins (6+7).

Trypsin inhibitors inhibit the enzyme trypsin, which reduces protein digestion, so we want as little in soy as possible.

Image 6: SDS page of different fermentation methods and their influence on protein size and the breakdown of anti-nutritional factors

Take a closer look at the blue bands inside the red box in image 6.

Column 2 (KTI) shows the antinutrient Kunitz Trypsin inhibitor or KTI/TI. In column 3, you can see the signal from TI weakened – and you can conclude that the heat treatment of soybean meal has positively reduced TIs.

Look at columns 4+5, lacto fermentation, and column 6, yeast fermentation. Here you see that the TI band has faded further.

And so, fermentation reduces the number of ANFs present beyond heat treatment.

The sharp-sighted will quickly discover that column 5 is the most effective fermentation technique to reduce TIs.

Want to dive deeper into why ANFs are bad for young animals? Then here’s an elaboration.

ANFs in soy

What are trypsin inhibitors?

Trypsin inhibitors (TI/TIA/KTI) and lectin reduce growth and can result in digestive disorders (2). TI are proteins that inhibit the effect of the digestion enzyme Trypsin. A large number of Tis in the soy means poorer utilisation of protein from the feed – Methionine and Cystine (1) in particular. The protein is resilient towards changes in the stomach pH. In the feed industry, soy is heat treated to reduce the content of TI – just like consumers boil the soybean before eating.

Fermentation, though, can reduce the content of trypsin inhibitors beyond heat treatment.

What is beta-conglycinin?

β-Conglycinin is known for its ability to cause allergic reactions. Heat treatment and fermentation help inactivate the antigen in Beta-conglycinin, causing allergic reactions (5). Beta-conglycinin can be detected on the SDS page gel at 50 Kilo Daltons (image 6).

What are raffinose and stachyose?

Raffinose and stachyose are sugars (galacto oligosaccharides) and a part of the group known as dietary fibre. Pigs can digest neither raffinose nor stachyose because the animals lack the specific digestive enzyme alfa-galactosidase. As a result, the fibres pass through the stomach and small intestines undigested. Dietary fibres can cause bloating and speed up the passage time feed. Galacto oligosaccharides work counterproductive because they reduce the digestibility of soy and worsen the feed utilisation and growth for pigs and poultry (3).

Unlike other ANFs, Raffinose and Stachyose are unaffected by heat treatment. And fermentation or enzyme treatment is needed to reduce the undigestible sugars.

During fermentation, lactic acid bacteria produce alfa-galactosidase breaking down raffinose and stachyose before the soy protein is fed to the animals.

Enough about ANFs. Let’s talk about the other important benefits of fermentation.

Fermentation produces new beneficial compounds

During fermentation, protein, minerals, and vitamins, but another fascinating process occurs.

When soy is digested, the plants’ defence system is activated to protect the plant—typically causing problems for the animal feeding on the plant. When we use fermentation, it resembles a pre-digestion of the feedstock, thereby solving the problem. There are plenty of examples of defence mechanisms in plants we can use to fight infection.

That way, pre-digestion, like fermentation, contributes to beneficial bioactive compounds.

An example is antibiotics produced by mushrooms. And so, defense mechanisms can be used to improve health – naturally.

During lacto fermentation, compounds like organic acids, hormone-regulating compounds, vitamins etc., are produced. However, the compounds depend on the feedstock used for fermentation. This means that soy fermentation does not produce the same metabolites as the fermentation of rapeseed or seaweed. That is why combining different fermented feed sources is an advantage.

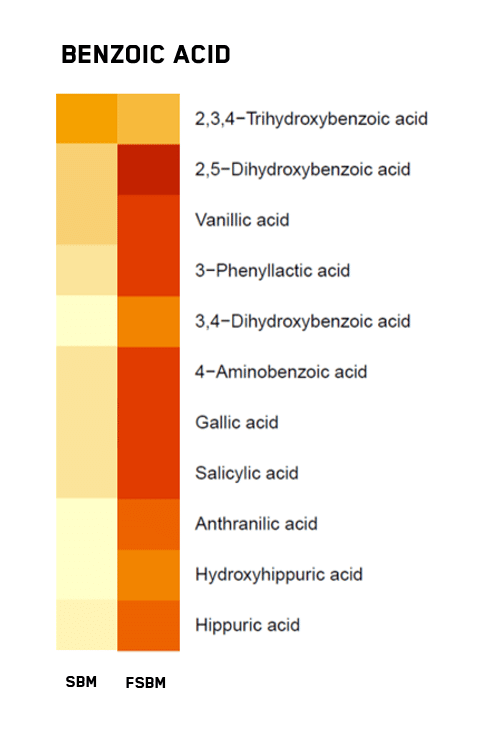

An example:

Below are various benzoic acids. The brighter, the lower the content of the specific fatty acid. The darker, the higher the content of fatty acids

SBM = soybean meal

FSBM = lacto-fermented soybean meal (EP200)

When you compare unfermented soybean meal (SBM) with fermented soybean meal (FSBM EP200), you will see that the colour intensity increases.

You have probably heard about benzoic acid already because you add it to your feed. The explanation for the increase of these valuable acids is that the bacteria we use also produce benzoic acid.

Image 7: Increase of benzoic acids during fermentation, metabolite study, 2022

What are the advantages of feeding fermented soy?

Feed for piglets and poultry still contains animal protein like fishmeal because it is highly digestible and has a broad nutritional profile, the high protein quality of fishmeal is reflected in an equally high market price but only sometimes reflected in the production results. Consequently, the feed industry is constantly searching for less costly plant protein sources for pigs and chickens.

When pigs and chickens are fed fermented soy, healthy and solid growth is ensured. The animals receive all the essential amino acids without damaging ANFs, and you can safely replace animal proteins like blood plasma and fishmeal without compromising on growth. The fermented soy will, for most producers, be a cheaper alternative to fishmeal and other types of animal protein.

When animals are fed highly digestible soy, a greater deal of the protein is utilised. Soy that cannot be digested tends to end up in the hindgut and cause diarrhoea. Some fermented soy proteins can be used as dietary supplements in periods with risks of digestive disturbances* (Diarrhoea).

EP200 is an example of a soy protein to be used for up to four weeks as a dietary feed to stabilise digestive disturbances in case of risk of, during periods of, or recovery from digestive disturbance.

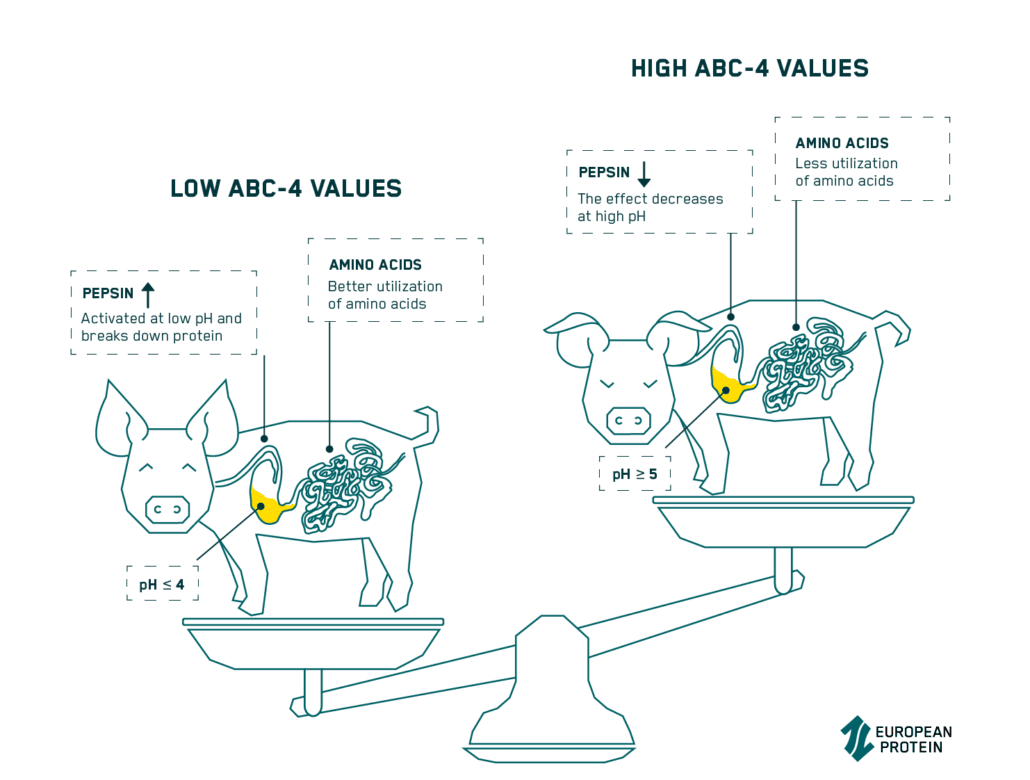

Animals can’t break down protein yet

Digestive enzymes like pepsin help animals break down protein in the stomach. Pepsin is effective at a low pH. Young animals with immature guts do not secrete enough hydraulic acid to lower the pH level in the stomach to a level where pepsin is activated to digest protein. Protein-rich feed increases stomach pH.

When the pH is too high, young animals are subject to both infections and undigested feed ending up in the hindgut, causing diarrhoea. Lacto-fermentation can help these young and vulnerable animals by keeping the acid binding capacity low (ABC-value) in the proteinrich feed.

Not all soy protein contributes to a low acid binding capacity: Get more information on which proteins help keep the pH down here.

Image 8: Young animals with immature guts do not secrete enough acid to reduce the pH of protein-rich feed to pH4

When does it pay off to use fermented soy?

Fermented soy brings the most value at the beginning of the animals’ life, where the guts’ ability to utilise protein is limited.

If you have three types of feeds for weaners, use soy protein in feed numbers 1 and 2.

Trials have shown that fermented soy can also boost growth in feed 3. The only problem is that costs will quickly catch up with the added growth and swallow your winnings.

If you decide to make your way through the list of published trials (like Steins) testing the most common soy proteins and soybean meals, you will find that some show a significant difference in production results while others fail to find a difference.

The key takeaway is that there’s a considerable variation in the results with either fermented soy protein or soybean meal. So do yourself a favour and test on your farm if you need more soy protein or soybean meal.

Want to compare the prices of different soy proteins based on the crude protein content? Check it out here.

If you want to know more about the types of fermentation, keep reading. Or sign up for our newsletter for more information on healthy feeding. Find the form at the bottom of the article.

Image 9: When to use fermented soybean meal in pig feed

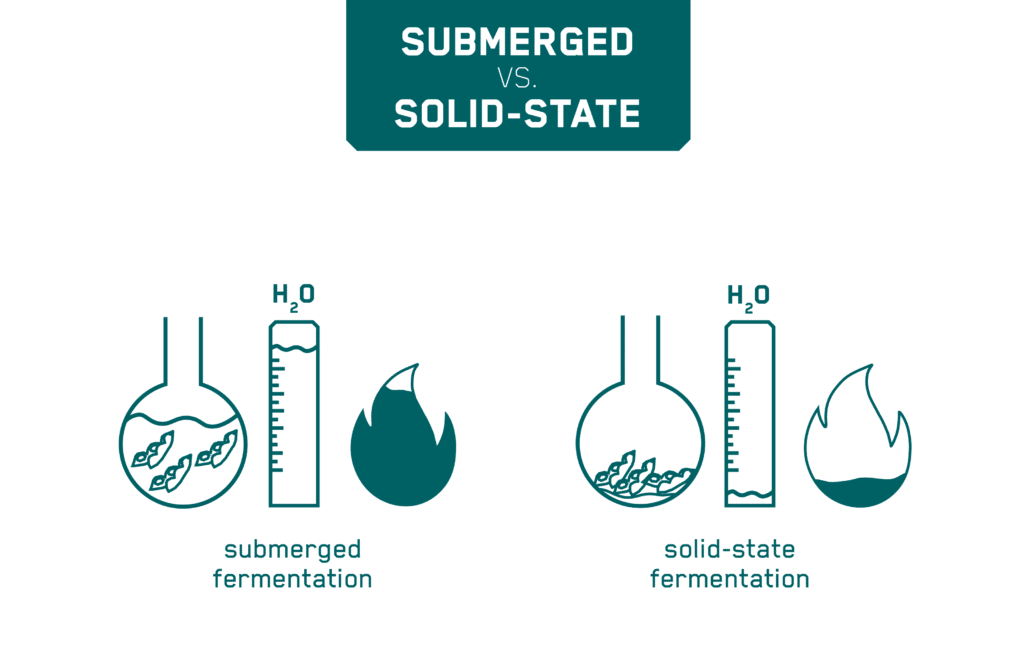

What’s the difference between wet and dry fermentation

There are two types of fermentation. A wet and dry fermentation.

They are known under a number of names. Wet fermentation is called liquid or submerged fermentation and is abbreviated SF, while dry fermentation is called surface or solid-state fermentation, SSF.

A wet fermentation takes place in large tanks, where soy is lowered into a wet mass, mainly consisting of water. The reason for calling it submerged. Wet fermentation is used to produce medicine, beer, yoghurt, and some types of soy protein.

A dry fermentation only makes the feedstock moist. Obvious to most, it demands far less water compared to wet fermentation. And less heating for the drying process. Dry fermentation can also be used to make fermented soy protein.

Image 10: Overview of the general differences between solid-state fermentation and submerged fermentation

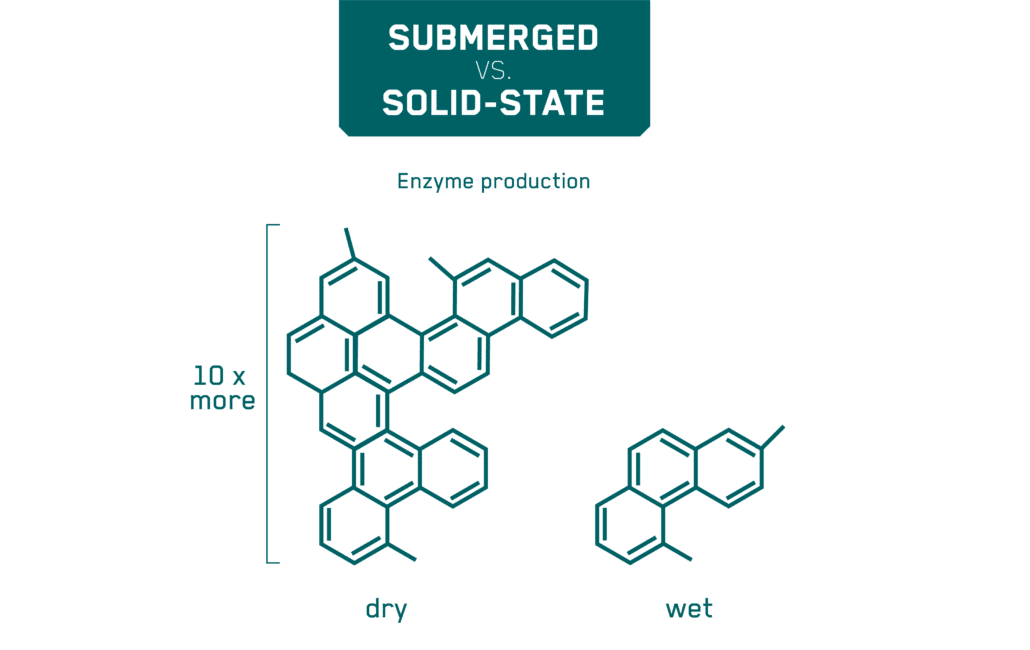

Which fermentation technique is better?

Both a dry (SSF) and a liquid fermentation (SF) have the capabilities of increasing the digestibility of nutrients in soy and reducing antinutrients (ANFs).

Regarding production costs, lower energy and water usage, solid-state fermentation wins. In addition, several studies have confirmed that the technology can be up to ten times more efficient at enzyme production than liquid fermentation (4).

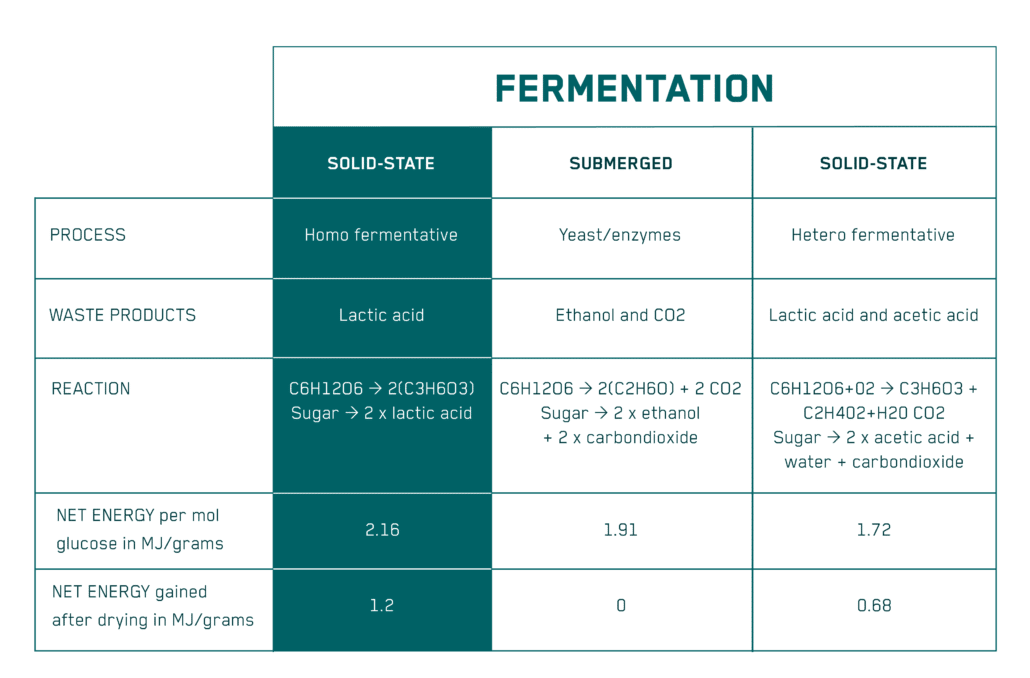

Several microorganisms can be used for the fermentation process. Each has its pros and cons.

Ingredients for fermentation

Lacto fermentation (homo fermentative)

Lactic acid bacteria are added to the soy to break down carbohydrates – the undigestible fibres. When homo fermentative lactic acid bacteria metabolise the carbohydrates, the bacteria produce the “waste product” lactic acid.

Lactic acid is used as an additive for animal feed to lower the pH in the stomach and keep bacteria from the surrounding environment in check. And so the waste products, coming from homo fermentative bacteria, contribute with added value to the soy protein.

An example of lacto fermentation is the soy protein EP200.

Lacto fermentation (hetero fermentative)

Besides lactic acid, heterofermentative bacteria produce acetic acid and CO2.

Consequently, some of the product vanishes into thin air as carbon dioxide. Therefore, energy levels of feed from a heterofermentative process are lower than that of a homofermentative process.

Yeast and enzyme fermentation (hetero fermentative)

Yeast fermentation is a wet fermentation, where yeast metabolises carbohydrates to ethanol and carbon dioxide. Yeast fermentation is also called ethanol fermentation. The waste product ethanol is unwanted in animal feed, and the soy undergoes heat treatment to make ethanol evaporate before the soy is fed to animals. Yeast fermentation is especially heavy on water, energy and CO2.

Here’s an overview of different soy fermentation processes.

Table 1: Overview of differences of hetero and homo fermentation

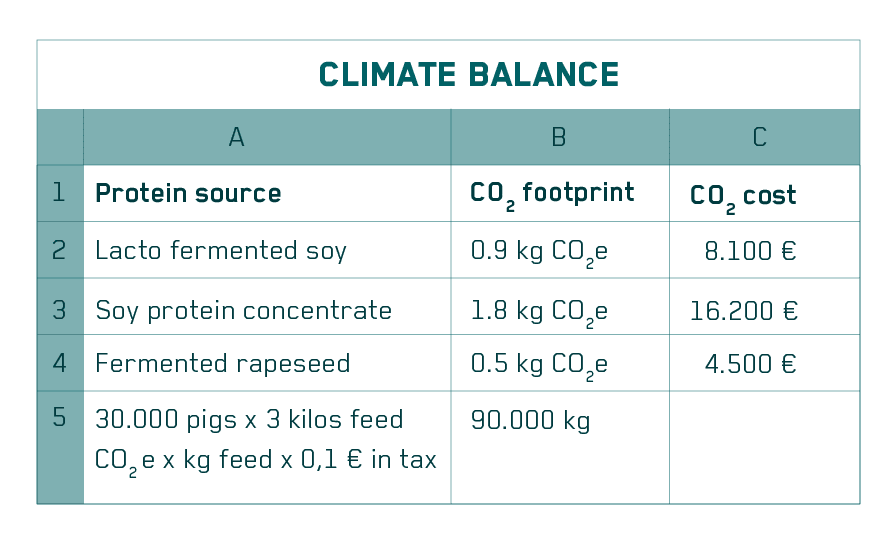

Did you know there are differences in the CO2 footprint of fermented soy protein? And that you should pay particular attention when using soybean meal or soy protein? Keep reading below.

Climate impact of soy

Soybeans have a terrible reputation in the climate debate. Primarily due to the South American soy, which in some cases comes from areas that used to be rainforests. When rainforest is cut down to produce soy, we lose biodiversity, and large composites of CO2, stored in the wet forest floor, are released. When the so-called loss is calculated, it’s called Land Use Change – or LUC.

And as you have probably figured out by now, south American soy scores high on the LUC list. As does palm oil from Borneo’s rainforests.

When we increase soy production, soy oil production also increases. Soy oil has less of a LUC impact than palm oil from Borneo. So on other parameters, soy production compensates a bit by benefitting the Rainforest in Borneo. The indirect effect is called ILUC or indirect land use change.

That’s why LUC values are complex to calculate.

The Danish thinktank, CONCITO, has calculated the climate impact of soybean meal to be 3.8 kg CO2e/kg. The global feed database, Global Feed Lifecycle Institute (GFLI), agrees. This database shows a value of 4.2 CO2e/kg with LUC and 0,57 without LUC. So, LUC matters.

The Danish Pig Research Center uses data from GFLI, but states the climate impact of dry matter basis delivered in Denmark. They state 6.09 kg CO2e/kg for soybean meal with LUC and 0.99 without.

The footprint increases if the soybean meal is refined to soy protein concentrate (SPC).

According to their calculations, soy protein concentrate accounts for 9.4 kg CO2e/kg and 1.8 without LUC. So about 1 kg CO2e/kg for the refinement process.

You cannot see the value for your own soy protein yet – the databases still use the same calculation regardless of brand and production method. So, for now, you will have to ask your protein supplier if you want to know the exact value of your feed.

What you can do in the databases is compare what different protein sources can do for your climate balance.

For the sake of comparison: Rapeseed meal has an impact of 0.49 kg CO2e/kg with LUC and 0.38 without. If we assume that the process to refine rapeseed for pigs costs as much as soy protein concentrate, you end up with 1.38 kg CO2e/kg compared to 1.8 CO2e/kg for soy delivered in Denmark.

With LUC, the difference adds up to 9.4-1.49 = 7.9 kg CO2e/kg saved.

If you are a farmer producing 30.000 pigs a year, with a tax of 0,1 EUR per kg CO2e, the taxes vary from 4,500 – 16,000 EUR in climate taxes per year.

“Well, I can’t feed rapeseed meal to weaners!” you might be thinking.

“Sure, you can – when it’s fermented”.

Read more about the fermented rapeseed EP100i here.

But for other countries where soy is native (no Rainforest), soy makes perfect sense.

So, the protein source you feed your animals matters. How much it matters depends on legislation and CO2 taxes, along with your access to locally produced protein.

Image 12: A hypothetical case of CO2 taxes for fermented rapeseed and fermented soy.

Soy and the climate balance

Different fermentation processes have different climate impacts. Especially dry versus wet fermentation and homo versus heterofermentative fermentation.

If you want to know the climate footprint for your climate balance, you have to get in touch with your supplier.

At European Protein, we work with Bureau Veritas to have a third-party verified carbon footprint on our soy, rapeseed and seaweed products. As soon as we have the results, they will appear in your inbox if you have signed up for our newsletter. If not. Sign up right here:

Sources

(1) https://svineproduktion.dk/publikationer/kilder/sh_medd/738

(2) https://en.wikipedia.org/wiki/Trypsin_inhibitor

(3) https://www.feedipedia.org/node/674

(4) https://smbb.mx/congresos%20smbb/cancun13/TRABAJOS/GIM/ProcessesFoodBeverages/GIMI0772.pdf and https://link.springer.com/chapter/10.1007/978-1-59259-991-2_27

(5) Sun P, Li D, Li Z, Dong B, Wang F. Effects of glycinin on IgE-mediated increase of mast cell numbers and histamine release in the small intestine. J Nutr Biochem. (2008) 19:627–33. doi: 10.1016/j.jnutbio.2007.08.007. Yi D, Hou Y, Mei H, Wang L, Hu CA, Wu GY. β-conglycinin enhances autophagy in porcine enterocytes. Amino Acids. (2017) 49:203–7. doi: 10.1007/s00726-016-2352-7

MORE NEWS

ABOUT EUROPEAN PROTEIN

European Protein is a Danish family-owned protein producer. We work to promote health and productivity for animals through functional and sustainable plant proteins. The company was founded in 2011 and has protein factories in Denmark, Ukraine and the US.

HEAD QUARTER

European Protein A/S

Vorbassevej 12, 6622 Bække, Denmark

+45 75 38 80 40, [email protected]

VAT No. 33643675

FACTORIES

Denmark

Mangehøje 4, 7300 Jelling, Denmark

+45 75 38 80 40, [email protected]

Ukraine

222-a Vokzalna Street, Rokytne 09600, Kyiv Region, Ukraine

+38 044 390 40 54, [email protected]

USA

1201 N Ellis Rd #7055, Sioux Falls, SD 57107, USA

+1 605-338-9775, [email protected]